Softening Point Of Glass

- Softening Point Of Glass Definition

- Polymer Softening Point

- Softening Point Of Glass Patterns

- Softening Point Of Glass Replacement

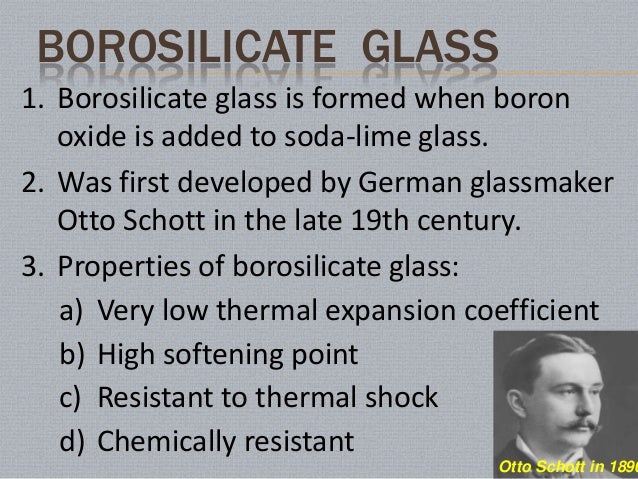

The softening point, at which the glass may slump under its own weight, is defined by a viscosity of 10 7.65 poise, the annealing point by 10 13 poise, and finally the strain point by 10 14.5 poise. Upon further cooling, viscosity increases rapidly to well beyond 10 18 poise. Softening point. The softening point is the temperature corresponding to a viscosity of 10 7.6 Poise (Bullseye & Wiki) or maybe 10 7.65 poise (Britannica). I didn’t figure out why I found two definitions for the softening point. At this viscosity glass softens sufficiently to be worked. The littleton softening point is the temperature at which the log (viscosity) for a glass is 6.6 Pa/s. This temperature is usually beyond that of typical service for the glass, but needs to be known - especially if firing an enamel or frit onto a glass article – giving an absolute maximum upper temperature limit for processing of the glass.

- For product formulation and quality control, a temperature called the softening point can be determined for these non-melting materials. There are different tests to determine these temperatures that vary by the material or the intended use. A related value is the glass transition temperature, which can be determined using similar tests.

- Softening Under Compression. The simplest form of softening point is to mount the TMA with a sample, use an applied force to lower a flat tip probe on the sample, and then heat up the sample (Figure 2). Two different flat tip probes are available to choose the optimal applied stress.

The softening point is the temperature at which a material softens beyond some arbitrary softness.[1] It can be determined, for example, by the Vicat method (ASTM-D1525 or ISO 306), Heat Deflection Test (ASTM-D648) or a ring and ball method (ISO 4625 or ASTM E28-67/E28-99 or ASTM D36 or ASTM D6493 - 11). A ring and ball apparatus can also be used for the determination of softening point of bituminous materials.[2]

Softening Point Of Glass Definition

See also[edit]

References[edit]

- ^Petrie, Edward (2006). Handbook of Adhesives and Sealants. McGraw-Hill. p. 146. ISBN0-07-147916-3.

- ^'Softening Point / Ring & Ball Apparatus'. http://cooper.co.uk. Cooper Research Technology Ltd. Retrieved 16 July 2015.External link in

website=(help)

Polymer Softening Point

Glass has a very large transition range. It also “mixes” well with components other than silica which affect it’s properties, including its state at various temperatures. In short, your question is simply too broad to give a solid, concise answer.

When consumer glass gets to a recycling plant, machines sort and clean the glass before turning it into cullet -- small pieces of crushed glass. The plants sell approximately 90 percent of the cullet to glass manufacturers, who mix it with limestone, soda ash and other raw materials. They then melt the mixture by heating it to temperatures of between 1,427 and 1,538 degrees Celsius (2,600 and 2,800 degrees Fahrenheit).

There are many, many art glass blowing studios all over the world, and they are increasing in number. Glass is a fascinating material. I would strongly recommend doing a web search for one near you. Talk to folk near you who have found ways to work glass. If you want to set up your own blowing setup, plan on at least $10K USD, without the building around it. Alternately you can buy a lampwork torch for about $500, but you’ll need proper ventilation and about $800 worth of tanks, hoses, valves, and of course, the glass itself.

If all you really want to do is blow a hole in the side of a bottle, you can get a MAPP2 gas torch for about $50 USD, but be forewarned, there’s something called COE (Coefficient of Expansion) which means different glasses expand and contract at different rates. That can shatter any work you do if you mix different glasses. That said, glass expands and contracts more than its cold sheer strength can handle a lot of the time, more than artists in the field would care to admit. (That’s why they added, effectively, borax and made borosilicate glass rendering a COE of about 33 - that’s low, meaning it’s less likely to shatter because of teperature changes, but it cools too fast for large work; most blowing glass is around 90–104.) If you expand one part of that bottle without heating the rest of it, you may do more than just blow a hole.

Be forewarned, too, given the relative complexity of glass, there’s a great deal of charlatanism and, um, knowledge-gap filling. We really don’t know all there is to know about glass. Despite that, many find glass work immensely therapeutic, rewarding, and it’s perpetually fascinating.

Softening Point Of Glass Patterns

If you do nothing else, check out the web offerings of The Corning Museum of Glass in upstate New York. Corning very likely made the display glass that’s on your phone.

Softening Point Of Glass Replacement

(Quora keeps telling me I need credentials to make this answer a bit more viable. Most of the stuff, numbers, I’ve compiled here can be found in various Wikipedia entries, and some of it, like the equipment you need, is out on glass blowing fora in multiple conversations. here’s my cred: I’m a compulsive search engine user. I blow glass, but not well enough to have my own studio. I rent. You can too.)

Create Just One VersionDolby Digital Plus is the only delivery format that can use the same stream for delivery to TVs, set-top boxes, and mobile devices. . And 7.1 channels can be delivered at data rates as low as 384 kbps. Consumers with legacy equipment will enjoy the same quality surround sound they've always had. Dolby digital plus software update. Ideal Companion for Video CodecsAdvanced compression algorithms allow delivery of discrete 5.1-channel surround sound at 192 kbps, half the data rate typically used.